- Weighing, Packaging and Quality Inspection systems

X-ray Inspection Systems

X-ray Inspection Systems

Showing 1–12 of 33 results

-

Read more

Autopac x-ray inspection systems

Autopac Systems design and manufacture a range of X-Ray Inspection Systems for use in the food industry, that are superior at automatically identifying metal and non-metal contaminants, missing or broken product, mass measurement, product shape confirmation, detecting packing voids and confirming fill levels.

Inspection of the product is achieved by the computer controlled ‘low energy’ generator, advanced sensor technology and the unique image processing system that make the Autopac X-ray Inspection System reliable at detecting minute product variations that signal contamination or deviation from the accepted specifications.

Autopac Systems form part of the Sapphire Alliance ®, a global group of the most experienced X-ray Inspection companies, who are collaborating to produce the most reliable, best supported X-ray Inspection systems on the market.

-

Read more

Flat Belt X-ray Systems

High resolution x-ray systems for cartons, pouches and other conveyed packaged products.

-

Read more

Large Product & Case X-ray Systems

A range of standard and custom case inspection systems to allow for finding small contaminants in even the largest cases.

-

Read more

Bulk Flow X-ray Systems

A range of standard and custom case inspection systems to allow for finding small contaminants in even the largest cases.

-

Read more

Can X-ray Systems

Single and double beam systems offer varying levels of sensitivity for any application.

-

Read more

Glass Jar & Bottle X-ray Systems

Single, double and triple beam systems offer varying levels of sensitivity for any application.

-

Read more

Pipeline X-ray Systems

Inspection of virtually any pumpable product.

-

Read more

Upright Pouches and Container X-ray Systems

High speed x-ray inspection of plastic bottles, retort pouches, composite cans or other upright products.

-

Read more

High Resolution X-ray Systems

Autopac/Sapphire APS Technology enables resolving of the finest features in any product.

-

Read more

Wide Format X-ray Systems

Conveyor belt widths from 460 to 1830mm without sacrificing sensitivity.

-

Read more

G10 Bulk Flow X-ray System

The G10 bulk flow x-ray system represents the most innovative offering in the field of automatic inspection.

It combines the advanced linear array technology with inspection algorithms proven for the most difficult inspections. Autopac automatic X-ray inspection systems are unrivalled in the industry for sensitivity, speed and sophistication of detection. The result is a system that demonstrates superior performance in identifying contaminants, such as metal, stone, glass, bone and certain plastics. Results are consolidated to give a series of integrated reports.

Inspecting at rates of up to 500 cubic feet per hour, these systems are deployed widely for bulk products such as nuts, grains, fruit, cereals and vegetables. The G10 Bulk Flow conveyor inspection system can inspect virtually any continuous bulk product flows that can travel by conveyor, guaranteeing your product andpackaging integrity, so vital to commercial success and brand reputation.

-

Read more

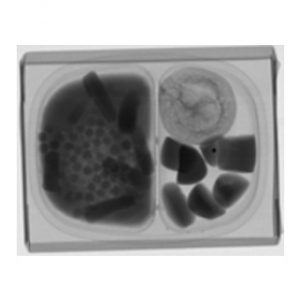

G10 X-ray System

The G10 conveyor x-ray inspection systems are the most compact and economical models in the Autopac series. They represent an entry level solution including both mass and contaminant checks for organizations looking to deploy x-ray technology which is unrivalled in the industry for its speed, sensitivity and sophistication of detection.

The G10 series is designed for simple and efficient operation, with fully adaptive inspection and exceptionally easy to understand operating procedures. Only 6 parameters are needed to give full inspection control of contaminant and mass inspection.

Like the larger and faster machines of the G series range, the G10

x-ray systems are deployed in the food processing industry, for packaged products such as confectionary, frozen products, bakery and ready meals. They are also ideal for loose product flows such as raisins, nuts and freeze-dried fruit. G10 systems can inspect virtually any discrete packaged items or continuous bulk product flows that can travel by conveyor.Using advanced linear array technology, the G10 exhibits superior performance in identifying contaminants such as metal, stone, glass, bone and certain plastics. It also effectively scans for product mass and detects under-fill and over-fill conditions to guarantee your product and packaging quality.